Industrial Manufacturing Training in the USA

Introduction to Industrial Manufacturing Training

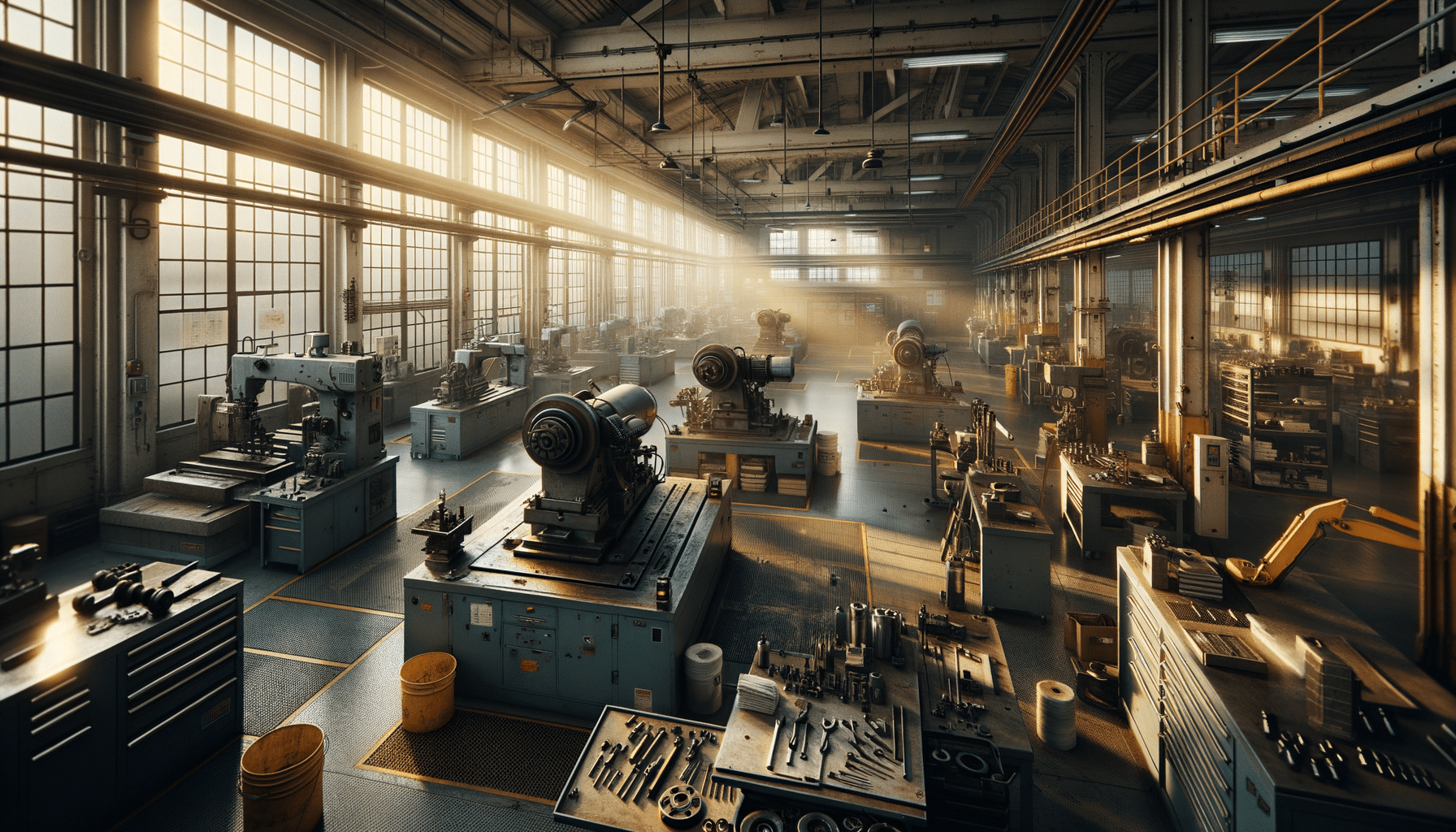

Industrial manufacturing is a cornerstone of the American economy, contributing significantly to both employment and GDP. As the sector evolves with technological advancements, the demand for skilled workers continues to rise. Industrial manufacturing training plays a crucial role in preparing individuals to meet the challenges of modern manufacturing environments. These training programs are designed to equip workers with the necessary skills, knowledge, and hands-on experience to excel in various manufacturing roles. With a focus on practical learning and the latest technologies, these programs ensure that participants are well-prepared for the dynamic demands of the industry.

The Importance of Specialized Training Programs

Specialized training programs in industrial manufacturing are essential for several reasons. Firstly, they provide a comprehensive understanding of manufacturing processes, enabling workers to handle complex machinery and equipment with confidence. These programs often include modules on safety protocols, quality control, and efficient production techniques, ensuring that trainees are well-rounded professionals. Additionally, specialized training helps bridge the skills gap in the industry, addressing the shortage of qualified workers. By offering targeted education, these programs enhance career prospects and contribute to the overall competitiveness of the manufacturing sector.

Moreover, specialized training programs often collaborate with industry leaders to stay abreast of the latest technological advancements. This collaboration ensures that the curriculum is relevant and up-to-date, providing trainees with knowledge that is directly applicable to real-world scenarios. As a result, graduates of these programs are highly sought after by employers, who value their expertise and readiness to contribute to the workplace from day one.

Key Components of Industrial Manufacturing Training

Industrial manufacturing training programs typically encompass a range of key components designed to provide a holistic educational experience. These components include:

- Theoretical Instruction: Courses cover the fundamental principles of manufacturing, including materials science, production planning, and engineering concepts.

- Hands-On Experience: Practical training in workshops and labs allows trainees to apply theoretical knowledge to real-world situations, enhancing their problem-solving skills.

- Technology Integration: Training on the latest manufacturing technologies, such as automation and robotics, prepares participants for modern manufacturing environments.

- Safety and Compliance: Emphasis on safety standards and regulatory compliance ensures that trainees are aware of industry best practices and legal requirements.

By integrating these components, industrial manufacturing training programs produce well-rounded professionals who are equipped to tackle the challenges of the industry.

Benefits of Industrial Manufacturing Training

Industrial manufacturing training offers numerous benefits to both individuals and the industry as a whole. For individuals, these programs provide a pathway to gainful employment and career advancement. By acquiring specialized skills, trainees can access a wide range of job opportunities in various manufacturing sectors, from automotive to aerospace. Additionally, the hands-on experience gained during training enhances their confidence and competence, making them valuable assets to employers.

For the industry, training programs help maintain a steady pipeline of skilled workers, ensuring that companies can meet production demands efficiently. This not only boosts productivity but also enhances the competitiveness of the manufacturing sector on a global scale. Furthermore, trained workers are more likely to adhere to safety protocols and quality standards, reducing the risk of accidents and defects. As a result, industrial manufacturing training contributes to the sustainability and growth of the sector.

Future Trends in Industrial Manufacturing Training

The future of industrial manufacturing training is shaped by emerging trends and technologies. As the industry moves towards greater automation and digitization, training programs are increasingly incorporating elements of Industry 4.0. This includes instruction on smart manufacturing systems, the Internet of Things (IoT), and data analytics. By embracing these trends, training programs prepare workers for the factories of the future, where digital skills are as essential as mechanical expertise.

Additionally, there is a growing emphasis on continuous learning and upskilling. As technologies evolve rapidly, workers need to update their skills regularly to remain relevant in the job market. Training programs are adapting by offering modular courses and online learning options, providing flexibility for workers to learn at their own pace. This approach ensures that the workforce remains agile and adaptable, ready to embrace new challenges and opportunities in the ever-changing manufacturing landscape.