Industrial Manufacturing Training Opportunities in Germany

Introduction to Industrial Manufacturing Training

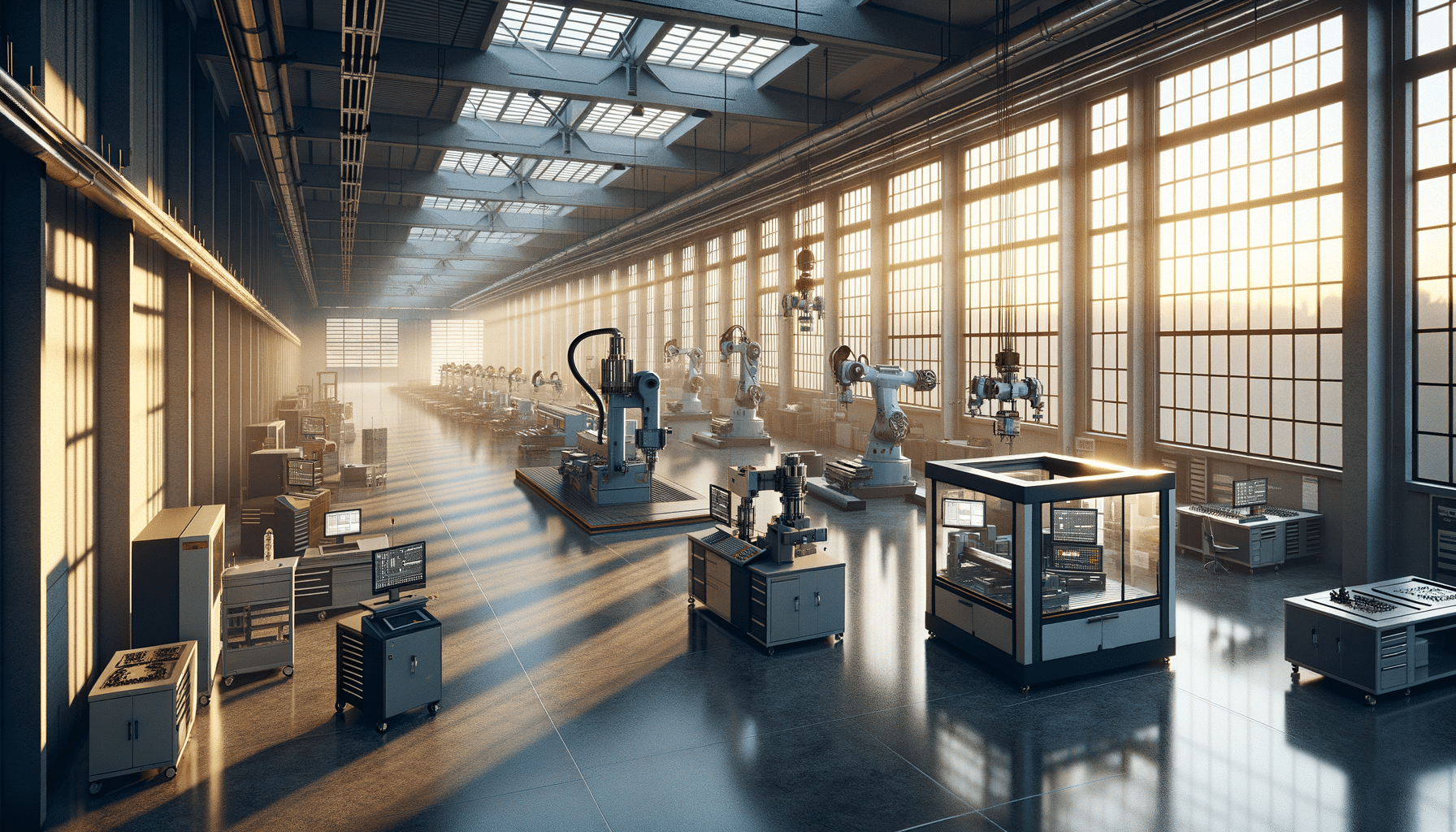

Germany is renowned for its robust industrial sector, marked by innovation and high-quality production standards. As the fourth largest economy in the world, Germany’s industrial landscape offers a multitude of opportunities for those looking to enter this dynamic field. Industrial manufacturing training programs are designed to equip individuals with the technical skills and knowledge required to thrive in this environment. These programs are crucial for bridging the gap between theoretical knowledge and practical application, ensuring that the workforce is well-prepared to meet the demands of modern manufacturing processes.

Training in industrial manufacturing is not just about learning how to operate machinery; it encompasses a wide range of skills, including quality control, safety protocols, and process optimization. This comprehensive approach ensures that trainees are versatile and capable of adapting to various roles within the industry. With the rapid advancement of technology, such as automation and digitalization, continuous learning and skill enhancement have become integral parts of a successful career in manufacturing.

For residents of Germany, these training programs offer a pathway to stable and rewarding careers. As industries continue to evolve, the demand for skilled workers who can manage complex manufacturing systems is on the rise. Therefore, engaging in industrial manufacturing training can significantly enhance one’s employability and career prospects.

Structure and Components of Training Programs

Industrial manufacturing training programs in Germany are structured to provide a balanced mix of theoretical instruction and hands-on experience. Typically, these programs are offered through vocational schools, technical colleges, and industry associations. The curriculum is designed to cover key areas such as:

- Technical Skills: Training on operating and maintaining manufacturing equipment.

- Quality Assurance: Ensuring products meet the required standards.

- Safety Protocols: Understanding and implementing workplace safety measures.

- Process Optimization: Learning how to improve efficiency and reduce waste.

In addition to these core areas, training programs often include modules on emerging technologies such as Industry 4.0, which encompasses the integration of cyber-physical systems, the Internet of Things (IoT), and cloud computing in manufacturing. This ensures that trainees are not only proficient in current practices but are also prepared for future advancements in the industry.

Hands-on training is a critical component of these programs, allowing participants to apply their theoretical knowledge in real-world settings. This practical experience is often gained through internships or partnerships with local industries, providing invaluable insights into daily operations and challenges faced by manufacturing companies.

Benefits of Industrial Manufacturing Training

Engaging in industrial manufacturing training offers numerous benefits to individuals and the industry as a whole. For individuals, these programs provide a clear pathway to employment, as they equip participants with the skills and certifications needed to secure positions within the manufacturing sector. The focus on practical, hands-on experience ensures that graduates are job-ready, reducing the need for extensive on-the-job training.

Moreover, these training programs foster a culture of continuous learning and skill development, which is essential in an industry characterized by rapid technological advancements. By staying abreast of new technologies and methodologies, workers can maintain their relevance and competitive edge in the job market.

For the industry, well-trained workers contribute to higher productivity, improved product quality, and enhanced safety standards. This not only boosts the reputation of individual companies but also strengthens the industrial sector as a whole, positioning Germany as a leader in global manufacturing.

Challenges and Opportunities in Industrial Manufacturing Training

While industrial manufacturing training offers numerous advantages, it also presents certain challenges. One of the primary challenges is keeping the curriculum up-to-date with the latest technological advancements. As industries are rapidly adopting automation and digitalization, training programs must evolve to incorporate these new technologies and ensure that trainees are well-prepared for the future.

Another challenge is attracting and retaining participants in these programs. There is often a perception that manufacturing jobs are less attractive compared to other career paths, which can deter potential trainees. However, with the right marketing and outreach efforts, these misconceptions can be addressed, highlighting the rewarding nature and growth opportunities within the manufacturing sector.

Opportunities abound for those who choose to pursue industrial manufacturing training. The demand for skilled workers is consistently high, and with the right qualifications, individuals can explore various career paths, from technical roles to management positions. Additionally, the skills acquired through these programs are transferable across different industries, providing flexibility and mobility in one’s career.

Conclusion: The Future of Industrial Manufacturing Training in Germany

The future of industrial manufacturing training in Germany looks promising. As the industry continues to evolve, so too will the training programs that support it. By staying attuned to technological advancements and industry needs, these programs can continue to provide valuable skills and knowledge to the workforce.

For residents of Germany, engaging in industrial manufacturing training is an investment in their future. It opens doors to stable and rewarding careers while contributing to the strength and competitiveness of the national economy. As industries increasingly rely on skilled professionals to navigate complex manufacturing processes, the importance of comprehensive training programs cannot be overstated.

In conclusion, those considering a career in industrial manufacturing should take advantage of the diverse training opportunities available in Germany. By doing so, they can position themselves at the forefront of innovation and excellence in the manufacturing sector.